aluNID®, manufacturer of aluminum honeycomb is committed to quality education (SDG 4) and affordable and clean energy (SDG 7), for this reason, has decided, for yet another year, to sponsor the Forze H2 team, from Delft University in its quest to get hydrogen powered cars.

Last season, Forze H2 team secured a second place in the “Supercar Challenge” sports class, on the TT circuit in the Netherlands. Due to the good results and the great effort to achieve success, aluNID® is, once again, the official sponsor of Forze H2 Delft team. aluNID® supplies honeycomb core for the chassis of the new Forze IX vehicle.

Forze Hydrogen Electric Racing was the first student racing team to develop a hydrogen car that could beat other competitors in an official race. Thanks to aluNID® panel core performance and student engineering skills, the Forze VIII can accelerate from 0 to 100 km / h in less than 4 seconds, making it the first hydrogen race car to achieve this landmark.

In this new season, aluNID® will once again sponsor the team for the production of the new Forze IX car, which will be much more powerful and faster than its predecessor, the Forze VIII.

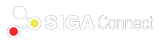

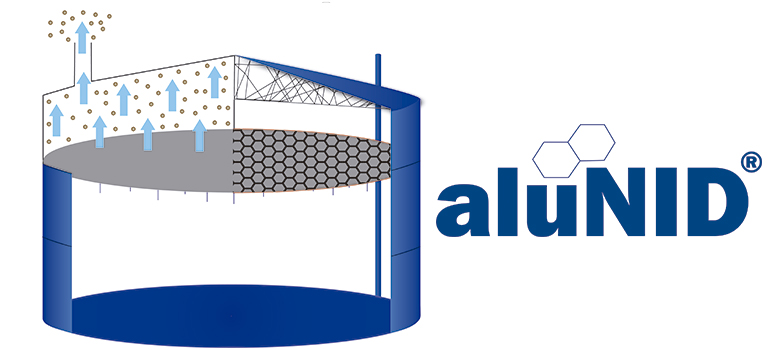

aluNID® provides the highest quality aluminum honeycomb core and which, thanks to its high strength, high rigidity and lightness, fulfills the crucial qualities for the construction of the chassis of a racing car. In this way, aluNID® enables outstanding potential and performance in the new generation of hydroelectric vehicles.