News

aluNID® even present in art galleries

The aluNID® aluminium honeycomb core is exhibited in Zurich thanks to ALUCOAT‘s collaboration with Swiss artist Esther Marthis.

Esther Marthis, an avant-garde artist who uses innovative materials in her works, has extensive experience in the world of the arts. On this occasion, she has decided to make the honeycomb core, aluNID®, an important element in her new temporary exhibition. Entitled “Nightshades“, the artist has exhibited works of different sizes in which she has applied spray paint to the honeycomb, creating incredible shadows and effects.

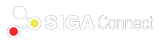

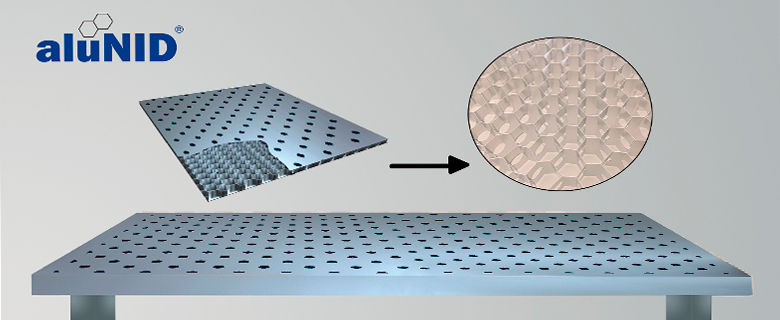

More and more artists and photographers are becoming interested in using aluNID® as a new element for their exhibitions, not only because of its enormous moulding capacity to create new decorative and artistic shapes, but also because thanks to the properties of aluminium, aluNID® has an excellent adhesion to paint, creating unique reflections and original shapes.

In addition, the aluminium honeycomb core is known for its special properties of lightness, excellent flatness, non-combustibility, strong compression and shear and for its particular structure, making it a very versatile material for use in countless applications, which is why artists have turned to it as a new element in their works.

aluNID®, present in all kinds of applications, even the least expected.